Industrial Shock Absorbers

MC4525-3

High energy absorption and robust design

Self-Compensating

Energy capacity 3,275 in-lbs/cycle

Stroke 0.91 inch

High energy absorption in a compact design and a wide damping range lead to huge advantages in practice. Alongside generally more compact designs, these small yet very powerful absorbers enable full use of the machine's performance. Self-compensating shock absorbers react to changing energy conditions, without adjustment.

CAD Drawings

Product-Downloads

Basic type MC45

| Mounting Instructions | 58 kB | 10/7/2010 | |

| en_US | |||

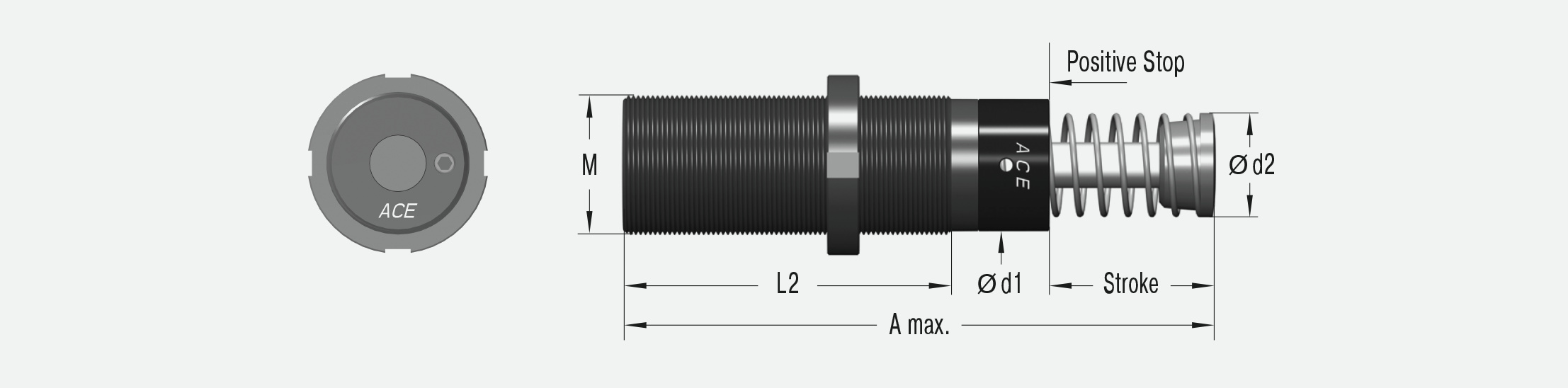

Dimensions

| Stroke | 0.91 inch |

| A max. | 5.69 inch |

| L2 | 3.72 inch |

| M | 1-3/4-12 UNF inch |

| d1 | 1.65 inch |

| d2 | 1.38 inch |

Technical Data

Energy capacity 3,275 in-lbs/cycle Energy capacity 950,000 in-lbs/h Energy capacity with oil recirculation 1,700,000 in-lbs/h Energy capacity with air/oil tank 1,400,000 in-lbs/h Effective weight min. 575 lbs Effective weight max. 2,300 lbs Hardness -3 Return Force max. 22.8 lbs Return Force min. 15.1 lbs Return Time 0.03 s Side Load Angle max. 4 ° Impact velocity range 0.5 ft/sec to 16.5 ft/sec. Other speeds on request. Operating temperature range 10 °F to 150 °F. Other temperatures on request. Mounting In any position Positive stop Integrated Material Outer body: Nitride hardened steel; Piston rod: Hard chrome plated steel; Rod end button: Hardened steel and corrosion-resistant coating; Return spring: Zinc plated or plastic-coated steel; Accessories: Steel with black oxide finish or nitride hardened Damping medium Automatic Transmission Fluid (ATF) | NoteA noise reduction of 3 dB to 7 dB is possible when using the special impact button. For emergency use only applications and for continous use (with additional cooling) it is sometimes possible to exceed the published max. capacity ratings. In this case, please consult ACE. Safety informationExternal materials in the surrounding area can attack the seal components and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Do not paint the shock absorbers due to heat emission. On requestSpecial oils, nickel-plated, increased corrosion protection, mounting inside air cylinders or other special options are available on request. |

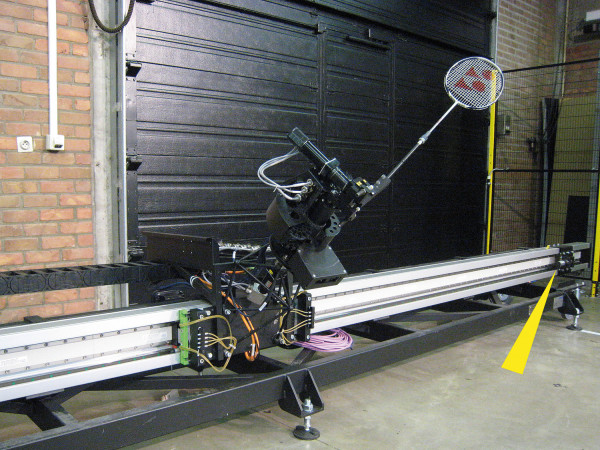

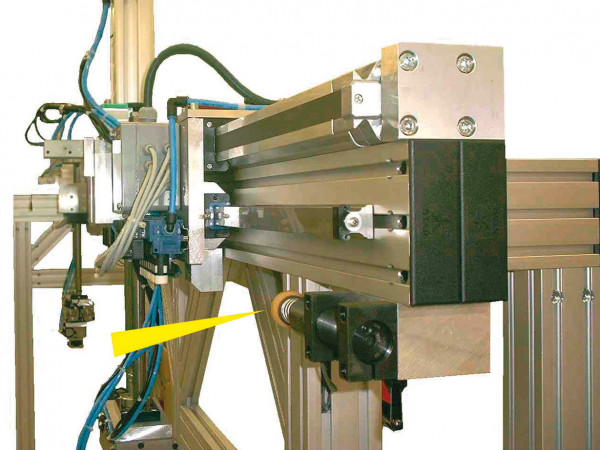

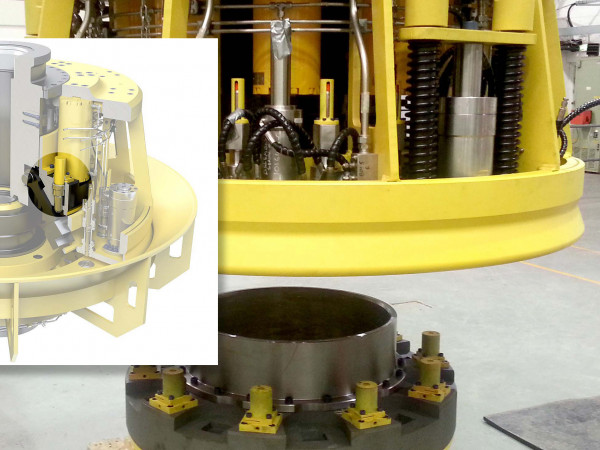

Application Examples

Application Areas

- Linear slides

- Swivel units

- Turntables

- Portal systems

- Machines and plants

- Tool machines

- Machining centers

- Z-axes

- Impact panels

- Handling modules

_FA_IMG_Single-01-cut-Labels_RGB-L_EN.jpg)

_FA_IMG_Single-01-cut_RGB-L.jpg)

250-0025(-0300)_TP_TECHdraw-SL-F_Chart_RGB-M_US.jpg)

250-0324(-0325)_TP_TECHdraw-SL-F_Chart_RGB-M_US.jpg)

250-0023_U_TP_TECHdraw-F-SR_RGB-M_US.jpg)

250-0024_U_TP_TECHdraw-F_RGB-M_US.jpg)

250-0428_StopBars_U_TP_TECHdraw-F-SR_RGB-M_US.jpg)

250-0041_U_TP_TECHdraw-F_RGB-M_US.jpg)

250-0072_F-StopCollar_U_TP_TECHdraw-F-SR_Web_RGB-M_US.jpg)

250-0092_TP_TECHdraw-F_RGB-M_US.jpg)

250-0731_TP_TECHdraw-F_RGB-M_US.jpg)

250-0778_TP_TECHdraw-F_RGB-M_US.jpg)