Hydraulic Feed Controls

VC2515FT

For precision adjustment of feed rates

Adjustable

Compression force max. 787 lbs

Stroke 0.59 inch

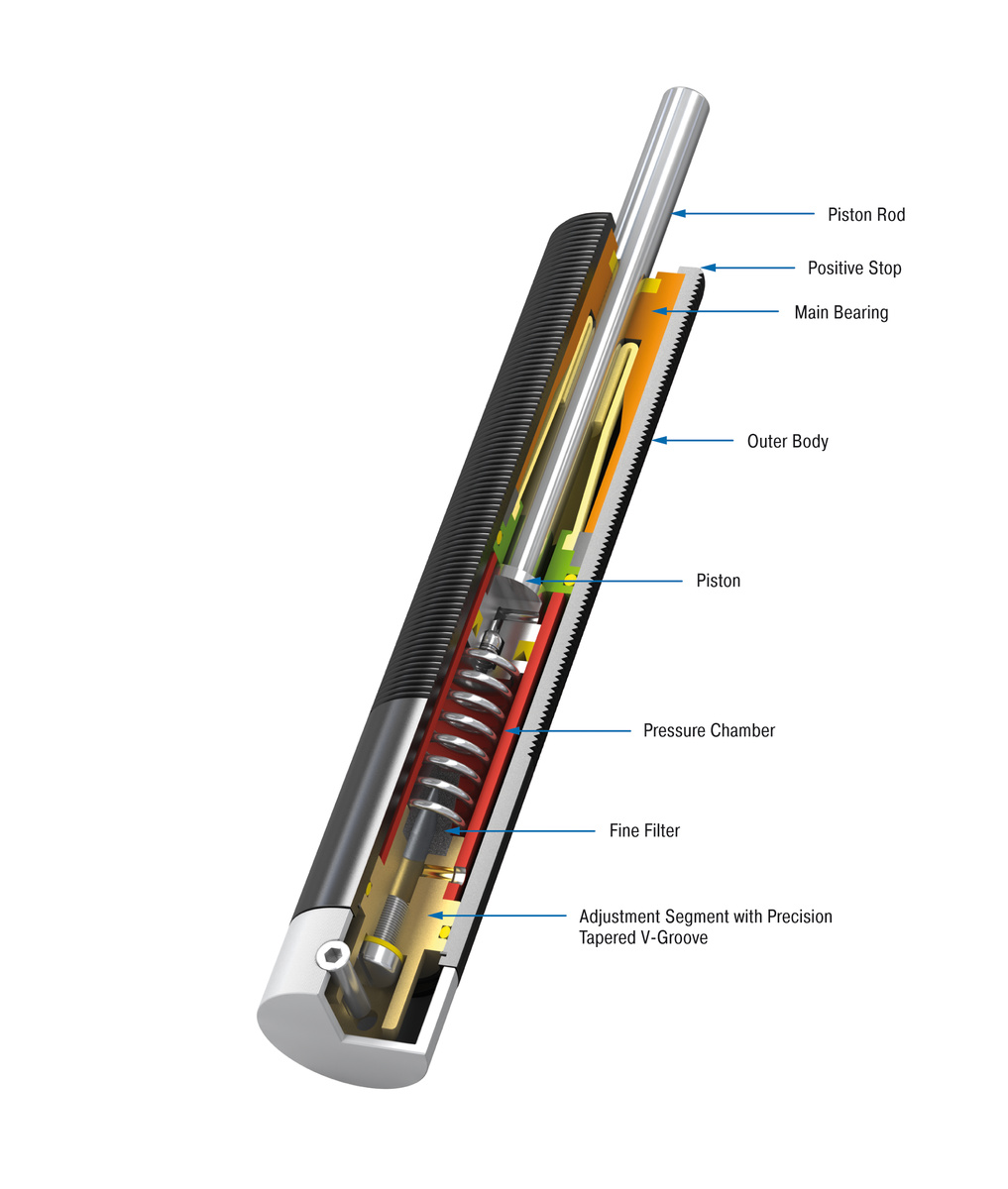

As the hydraulic oil is forced out through the throttle opening, a constant feed rate is achieved on the stroke. In the models up to 2.17"" (55 mm) stroke, the tried and tested rolling diaphragm, known from ACE shock absorbers, serves as a dynamic seal, as volume compensation of the piston rod and as a reset element.

CAD Drawings

Product-Downloads

Basic type VC25FT

| Mounting Instructions | 50.2 kB | 10/7/2010 | |

| en_US | |||

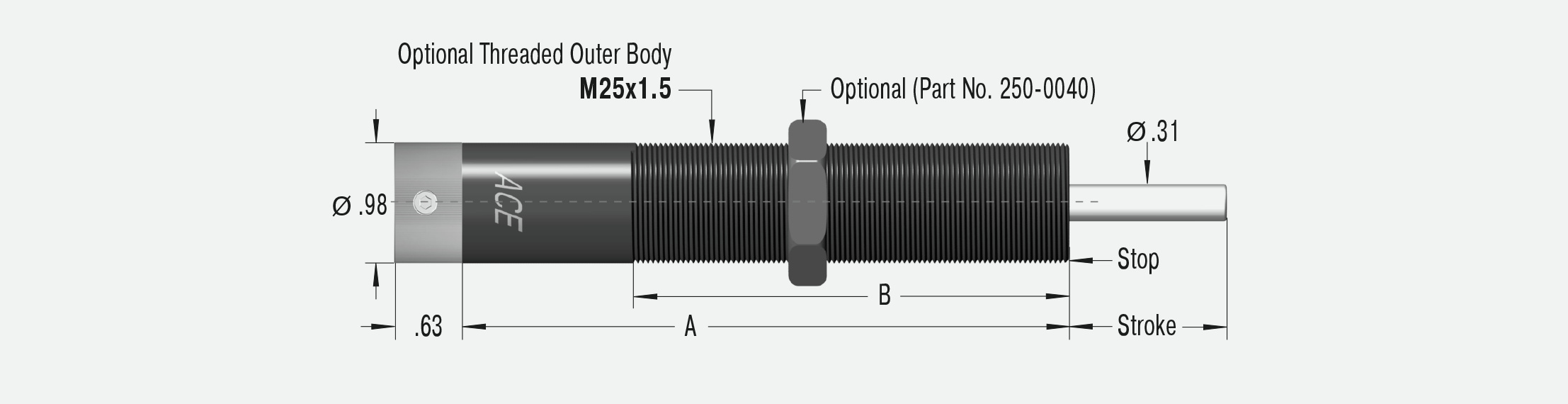

Dimensions

| Stroke | 0.59 inch |

| A | 5.04 inch |

| B | 3.15 inch |

| M | M25x1.5 inch |

Technical Data

Compression force min. 6.74 lbs Compression force max. 787 lbs Return Force min. 3.37 lbs Return Force max. 6.74 lbs Return Time 0.2 s Side Load Angle max. 3 ° Compression force 6.74 lbs to 787 lbs lbs Piston rod diameter Ø 0.31 in Impact velocity range At speeds of 0.98 ft/sec the maximum allowed energy is approx. 8.85 in-lbs for units up to 2.16 in stroke and approx. 17.70 in-lbs for units 2.95 in to 4.92 in stroke. Where higher energies occur use a shock absorber for the initial impact. Avoid high impact velocities. Adjustment Infinitely adjustable Positive stop External positive stops 0.04 in to 0.06 in before the end of stroke provided by the customer. Damping medium Oil, temperature stable Material Outer body: Black anodized aluminium; Piston rod: Hard chrome plated steel; Accessories: Steel with black oxide finish or nitride hardened Mounting In any position Operating temperature range 32 °F to 140 °F | NoteNylon button can be fitted onto piston rod. Unit may be mounted in any position. Safety informationDo not rotate piston rod, if excessive rotation force is applied rolling seal may rupture. External materials in the surrounding area can attack the seal components and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. On requestSpecial oil and other special options available on request. |

Application Examples

Application Areas

- Handling modules

- Linear slides

- Automatic machinery

- Conveyor equipment

- Absorption control

250-0044_M_TP_TECHdraw-F-dim_RGB-M_US.jpg)