Miniature Shock Absorbers

MC600MH2-V4A

Exceptionally high endurance with stainless steel corrosion protection

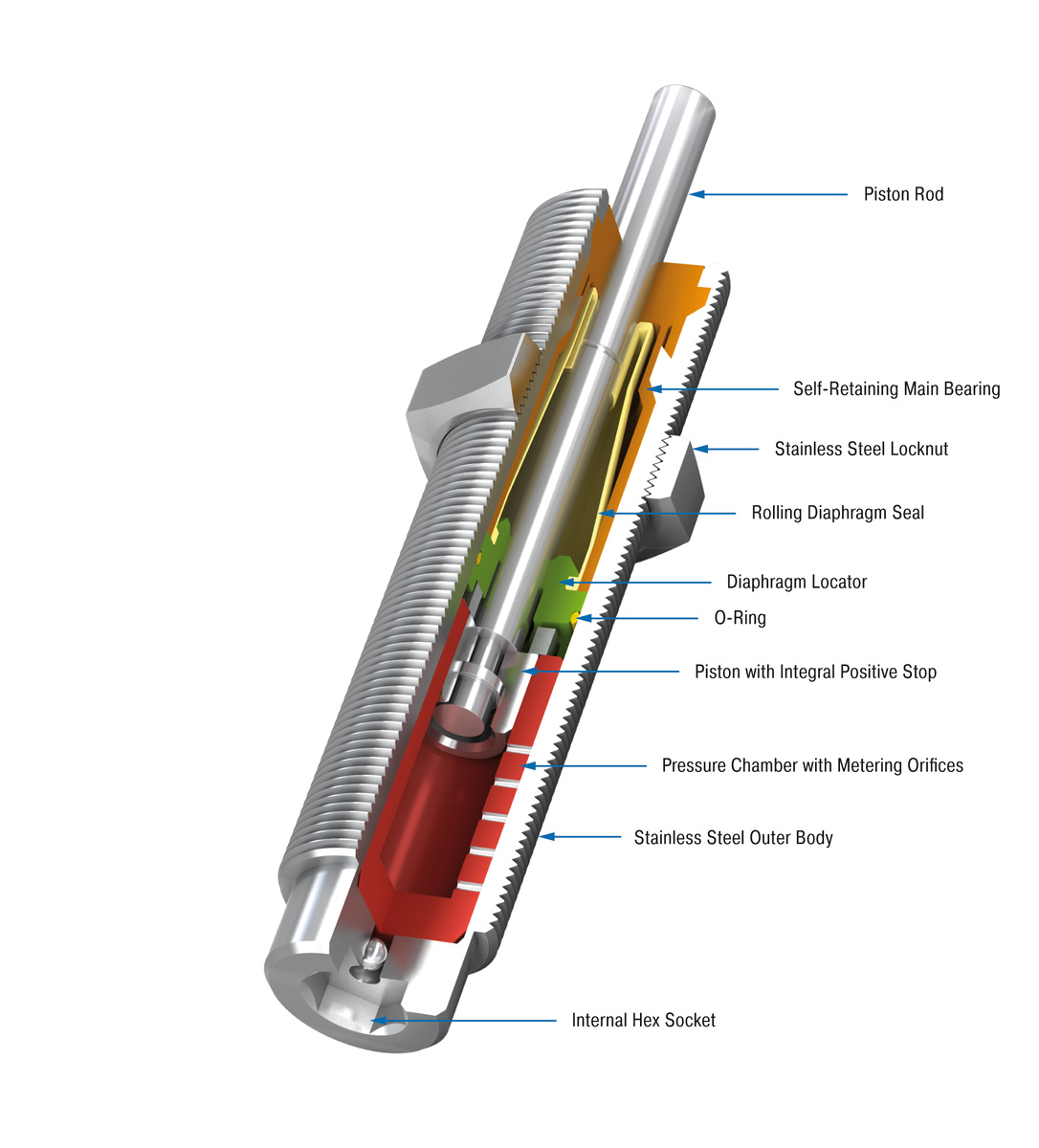

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology

Energy capacity 1,200 in-lbs/cycle

Stroke 1.0 inch

Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the stainless steel outer body and a complete range of stainless accessories (AISI 316L). Self-compensating shock absorbers react to changing energy conditions, without adjustment.

These self-compensating miniature stainless steel shock absorbers are used in medical and electro-technology, as well as marine, packaging, and chemical applications. Shocks can be filled with food-grade oil for food processing applications.

CAD Drawings

Product-Downloads

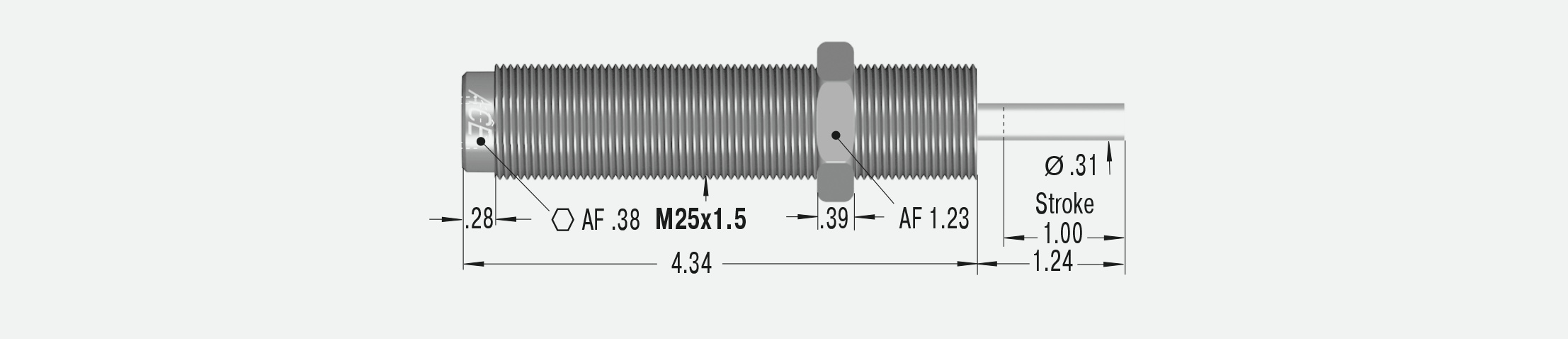

Dimensions

| Stroke | 1.0 inch |

| M | M25x1.5 inch |

Technical Data

Energy capacity 1,200 in-lbs/cycle Energy capacity 600,000 in-lbs/h Effective weight min. 880 lbs Effective weight max. 5,000 lbs Return Force min. 1.0 lbs Return Force max. 2.0 lbs Return Time 0.6 s Side Load Angle max. 2 ° Impact velocity range 0.22 ft/sec to 19.7 ft/sec. Other speeds on request. Operating temperature range 32 °F to 150 °F Mounting In any position Positive stop Integrated Material Outer body, Locknut, Accessories: Stainless steel (1.4404, AISI 316L); Main bearing: Plastic; Piston rod: Hardened stainless steel (1.4125, AISI 440C); Rolling diaphragm: EPDM Damping medium Oil, temperature stable | NoteIf precise end position datum is required consider use of the stop collar type AH. Safety informationExternal materials in the surrounding area can attack the rolling seal and lead to a shorter service life. Please contact ACE for appropriate solution suggestions. Suitable for use in pressure chambers up to 101.53 psi. On requestSpecial oil with food approval. Special threads or other special options available on request. |

250-0254-V4A_M_TP_TECHdraw-F-dim_RGB-M_US.jpg)

250-0443_M_TP_TECHdraw-F-dim_RGB-M_US.jpg)

250-0755_TP_TECHdraw-F-dim_RGB-M_US.jpg)

250-0436-V4A_M_TP_TECHdraw-F-dim_RGB-M_US.jpg)