Safety Shock Absorbers

SCS33-50

Industry design with high energy absorption

Self-Compensating or Optimized Characteristic

Energy capacity - in-lbs/cycle

Stroke 1.91 inch

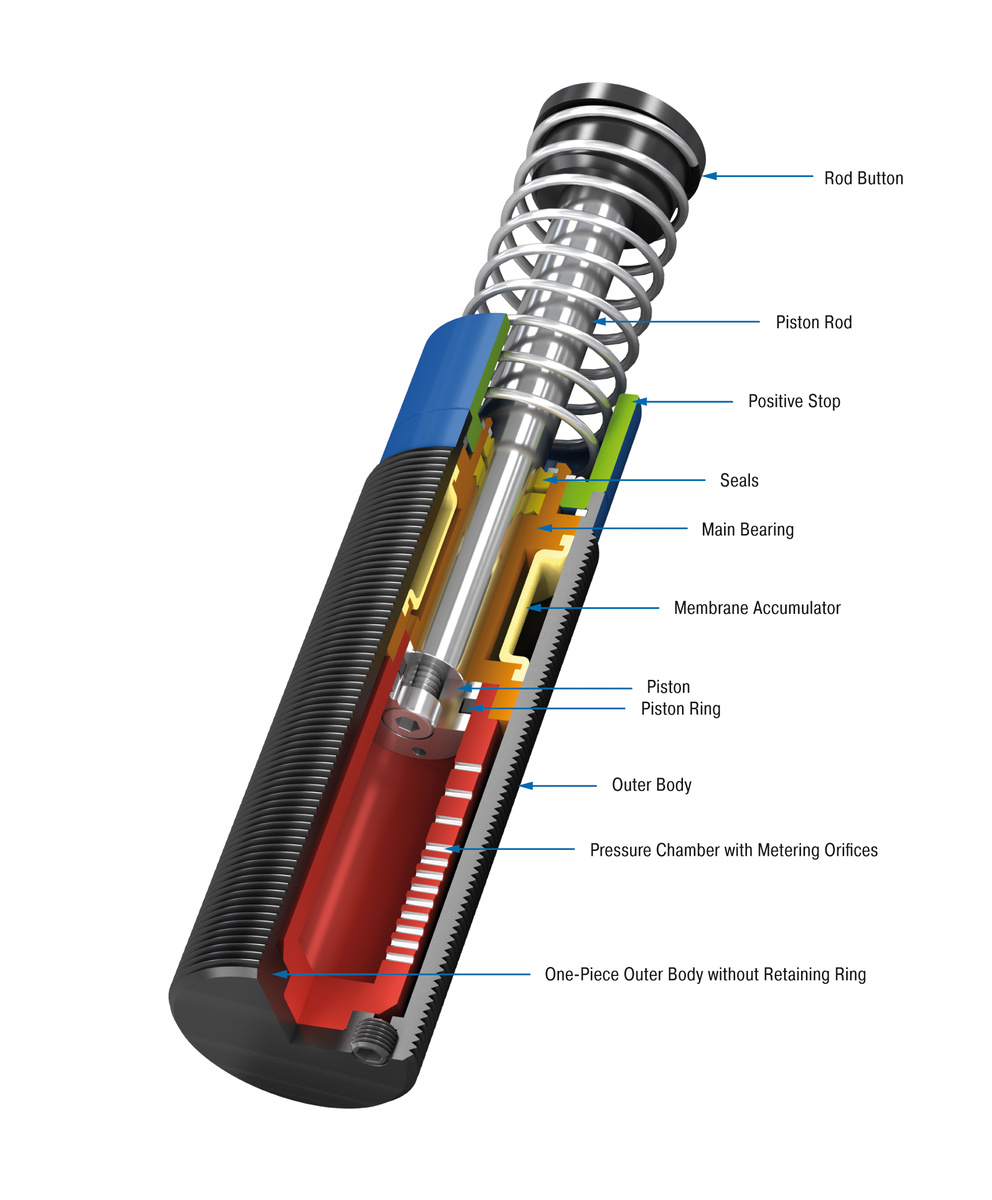

ACE uses our proprietary custom calculation program to design each shock absorber for the specific customer application. Customization helps reduce the risk of crashes and incorrect product sizing. Due to the optimized characteristic curve for the respective application, the energy absorption of these hydraulic machine elements can be increased to more than twice the level of the MAGNUM model of ACE industrial shock absorber per stroke. Users benefit from a service life of up to 1,000 full load emergency cycles with a very good price-performance ratio. Their compact design in sizes M33x1.5 to M64x2 makes them easy to integrate into current applications.

CAD Drawings

Product-Downloads

Basic type SCS33

| Mounting Instructions | 165.3 kB | 5/12/2021 | |

| en_US | |||

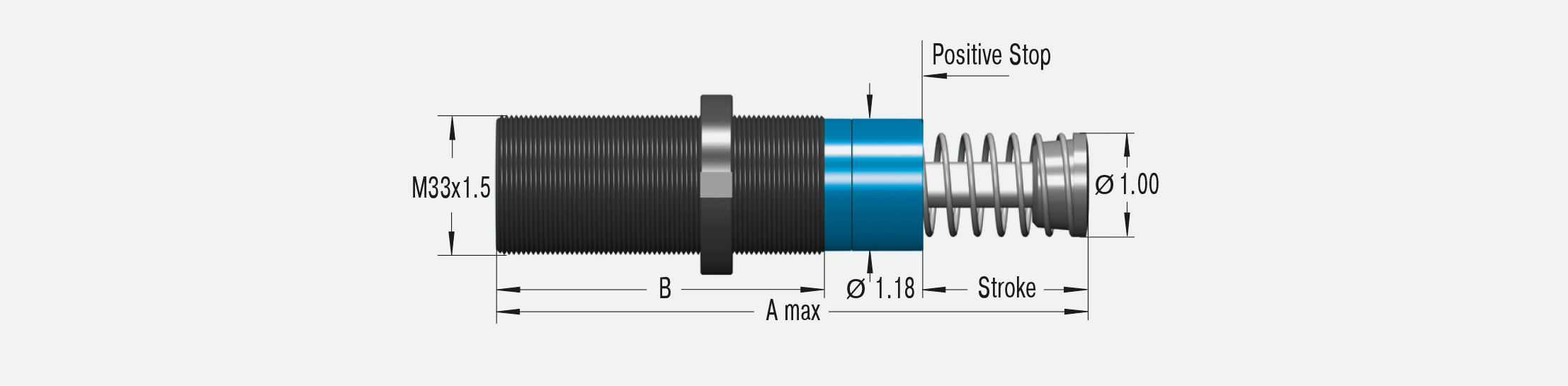

Dimensions

| Stroke | 1.91 inch |

| A max. | 7.44 inch |

| B | 4.25 inch |

| L1 max. | 3.39 inch |

| L1 min. | 1.26 inch |

| L3 | 3.66 inch |

Technical Data

Energy capacity - in-lbs/cycle Energy capacity self-compensating 5,487 in-lbs/cycle Energy capacity optimised 8,408 in-lbs/cycle Return Force min. 10.1 lbs Return Force max. 30.3 lbs Side Load Angle max. 2 ° Impact velocity range 0.06 ft/sec to 16 ft/sec. Other speeds on request. Operating temperature range 10 °F to 158 °F. Other temperatures on request. Mounting In any position Positive stop Integrated Material Outer body: Nitride hardened steel; Piston rod: Hard chrome plated steel; Rod end button: Hardened steel and corrosion-resistant coating; Return spring: Zinc plated or plastic-coated steel; Accessories: Steel corrosion-resistant coating Damping medium Automatic Transmission Fluid (ATF) | NoteThese slimline, high-performance safety shock absorbers are only designed for emergency stop situations. They can be used for a number of tasks in gantries and conveyor systems, processing centres or assembly machines. On requestSpecial oils, special flanges etc. |

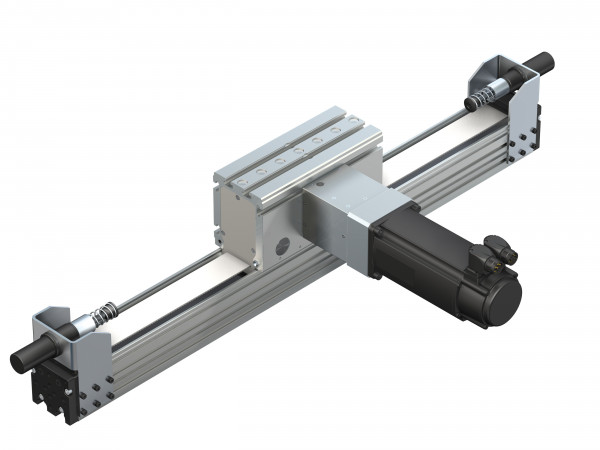

Application Examples

Application Areas

- Finishing and processing centers

- Conveyor systems

- Outer body: Nitride hardened steel; Piston rod: Hard chrome plated steel; Rod end button: Hardened steel and corrosion-resistant coating; Return spring: Zinc plated or plastic-coated steel; Accessories: Steel corrosion-resistant coating

- Test stations

- Machines and plants

- Swivel units

- Cranes

250-0292_M_TP_TECHdraw-F_RGB-M_US.jpg)

250-0293_M_TP_TECHdraw-F_RGB-M_US.jpg)

250-0015(-0294)_TP_TECHdraw-SL-F_Chart_RGB-M_US.jpg)